The installation of our fittings with the glass of the glass manufacturer is usually carried out on the building site by the assembling company from the specialist areas of interior design, glazing, carpentry or metal construction. However, the choice of glass to be used later is already relevant when selecting and ordering the fittings and systems. The type of glass preferred for the respective application and the appropriate glass thickness play a role here.

Important: Single-pane float glass (non-tempered plain glass) is not suitable or approved for unframed all-glass doors and installations due to its low bending strength and sharp-edged breakage pattern.

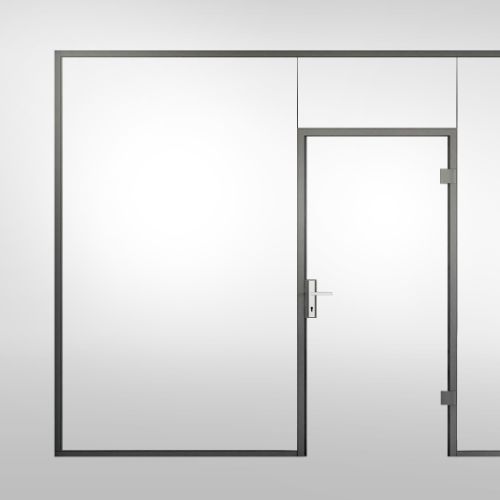

Our portfolio therefore includes fittings and systems for the following glass types:

TSG Toughened Safety Glass

- Standard glass thicknesses 8 / 10 / 12 / 15 and 19 mm

- High stress resistance. Approximately three times higher bending strength than float glass.

- Small crumbly breakage pattern in the rare event of glass breakage, low risk of injury.

- Attachment to the fitting / in the system by clamping.

LSG Laminated Safety Glass

Made of 2 x TSG (Toughened Safety Glass) or of 2 x STG (Semi Tempered Glass)

- Standard glass thicknesses (measures given in ca. mm; exact measures depend on the foils used) 10.8 / 11.5 / 12.8 / 13.5 / 16.8 / 17.5 mm

- Additional safety due to connecting foil between the two glass panes = residual load-bearing capacity after glass breakage of one or both panes.

- Mounting on the fitting / in the system by clamping with reduced clamping force and additional adhesive bonding (Clamp&Glue)

ISO Insulating Glass

Functional, hermetically sealed glazing unit consisting of at least 2 panes of glass. (The type of glass - possibly differing - used for the individual panes within an insulating glass unit depends on the respective structural conditions, e.g. expected wind load.)

- Standard glass thicknesses upto 49 mm

- The glass panes, which are firmly installed to form a unit, are separated in the surfaces by a sealed intermediate space and are only connected by a frame structure. Low energy loss due to the enclosed intermediate space filled with inert gas as a thermal insulation barrier.

- Assembly in the system by block-setting in the frame with subsequent sealing by glazing profile and rubber seal.

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/menu/DG-Menue-inspiration_referenzen_porsche_500x500px.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/menu/dg_menue_produkte_MUTO_Schiebetuerbeschlaege_293x150.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/menu/dg_Milieau_OFFICE_Arcos_geschl_293x150_Glastuerbeschlaege.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/produkte/eckbeschlaege_profilsysteme/dg_Milieau_MUNDUS_OFFICE_XL_293x150.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/produkte/glastrennwaende/uniquin/IM_UNIQUIN_2023Clamp_Cover80_TS_293x150.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/menu/dg_Milieau_FSW_EASY_Safe_halboffen_frontal_Glasschiebewaende_293x150.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/produkte/duschbeschlaege/dg_MORANO_menu.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/menu/dg_menue_produkte_Griffstange_griffe_293x150.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/produkte/justoLINE/justoLINE_Thumbnail_Web.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/menu/dg_menue_aktuelles_presse500x500.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/menu/ueber-uns_unternehmen_menu.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/ueber_uns/historie/Dg-ueber-uns_Historie-Luftbild.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/menu/DG-Menue-Ueber-uns-Qualitaet_500x500px.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/menu/DG-Menue-Ueber-uns-Nachhaltigkeit_500x500px.jpg)